Meticulous selection for top grade quality.

PRODUCTS

CONTACT

- Phone&WeChat&WhatsApp: +86-18966127786

+86-18968595687 - Email: [email protected]

[email protected] - Address: 3rd Floor, Room 103, Building 30, No. 1, Yuanbei Road, Fengjiang Street, Luqiao District, Taizhou City, Zhejiang Province, China

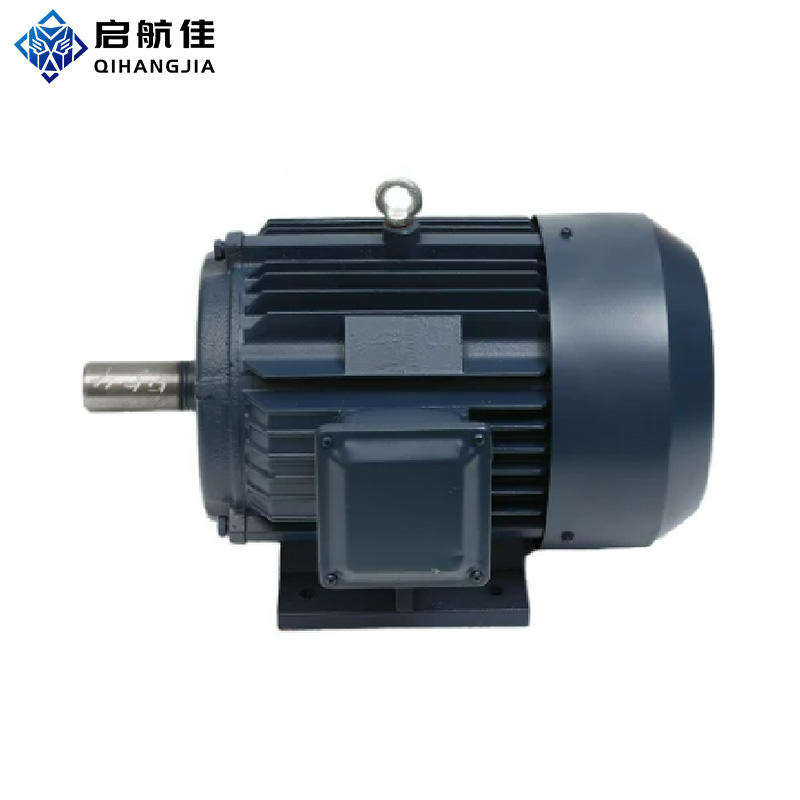

Three-phase asynchronous AC motor Suppliers

-

Yej Motor AC Motor Wholesale Electromagnetic Brake Three-Phase Asynchronous Motor Yej100L-2

-

Yd Series B3/B5/B35/B34/B14 Double Speed Three Phase 50Hz 380V Asynchronous Induction Motor

-

Ys801-2 Premium Efficiency Three Phase Asynchronous AC Electric Motor with Aluminum Alloy Shell

-

China Manufacturer AC Yvp Series 380V 3 Phase Induction Frequency Variable Speed Adjustable AC Motor

-

High Quality IEC Explosion-Proof Motor Ex Motor 0.37-400kw High Power Industrial Asynchronous Three-Phase AC Electric Motor

-

Yb2 Yb3 Series Three Phase Explosion Proof Induction Electric AC Motor

-

Cheapest Price Quality Design Three Phase AC Best Motor Water Pump Electrical Motor Induction AC Motor Asynchronous AC Motor

About Us

Founded in 2004, Qihangjia is located in Fengjiang Street, Luqiao, Taizhou, Zhejiang the country of water pumps, motors, and blowers in China. Our company is devoted to the development, manufacture, and sales of different types of agricultural pumps, and household pumps. project construction pumps, chemical canned pumps, and shin pumps. ac motors centrifugal Pump and blower concrete vibrator. Our company owns a total industrial area reaching 8000 square meters, more than 200 staff, and annual revenue of 80 million RMB.

News

-

Industry News 2024-05-03

In the dynamic landscape of industrial applications, innovation is the driving f...

View More -

Industry News 2024-04-26

In today's fast-paced world, where advancements in technology continue to reshap...

View More -

Industry News 2024-04-19

In the realm of residential plumbing, where water pressure is paramount for ever...

View More -

Industry News 2024-04-12

In the realm of modern agriculture, where efficiency and sustainability are para...

View More -

Industry News 2024-04-05

In the ever-evolving world of industrial machinery, the pursuit of efficiency an...

View More -

Industry News 2024-03-25

Wholesale jet pump systems offer numerous benefits for various industries and ap...

View More

Industry Knowledge Extension

What is a three-phase asynchronous AC motor? What is it for?

A three-phase asynchronous AC motor is a common type of motor that is commonly used in industrial and commercial applications such as driving pumps, fans, compressors, conveyor belts, and more.

The operating principle of this type of motor is based on the interaction between an alternating current and a rotating magnetic field. When the three-phase power supply is turned on, the coil in the motor will generate a rotating magnetic field, which will cause an induced current inside the rotor, thereby generating torque to make the rotor start to rotate.

Three-phase asynchronous AC motors are widely used in various industrial fields due to their simple structure, convenient use, and low maintenance costs.

How to choose a suitable three-phase asynchronous AC motor

To select a suitable three-phase asynchronous AC motor, the following factors need to be considered:

1. Power demand: Determine the required motor power according to the load demand. The rated power of the motor should be slightly greater than the demand of the load to ensure that the motor can work normally and avoid overload.

2. Speed requirement: Select the rated speed of the motor according to the speed required by the load. If the load requires variable speed, consider using a frequency converter to control the speed of the motor.

3. Voltage and frequency: The rated voltage and frequency of the motor should match the voltage and frequency of the power grid. If the voltage and frequency do not match, it may affect the performance and life of the motor.

4. Environmental conditions: Environmental conditions, such as temperature, humidity, and corrosiveness, must also be considered when selecting a motor. If the environmental conditions are harsh, it is necessary to select a motor with a suitable protection level.

5. Cost: Finally, the cost of the motor needs to be considered, including purchase cost and operating cost. Higher efficiency and longer life usually require higher cost inputs. What is a three-phase asynchronous AC motor? What is it for?

A three-phase asynchronous AC motor is a common type of motor that is commonly used in industrial and commercial applications such as driving pumps, fans, compressors, conveyor belts, and more.

The operating principle of this type of motor is based on the interaction between an alternating current and a rotating magnetic field. When the three-phase power supply is turned on, the coil in the motor will generate a rotating magnetic field, which will cause an induced current inside the rotor, thereby generating torque to make the rotor start to rotate.

Three-phase asynchronous AC motors are widely used in various industrial fields due to their simple structure, convenient use, and low maintenance costs.

How to choose a suitable three-phase asynchronous AC motor

To select a suitable three-phase asynchronous AC motor, the following factors need to be considered:

1. Power demand: Determine the required motor power according to the load demand. The rated power of the motor should be slightly greater than the demand of the load to ensure that the motor can work normally and avoid overload.

2. Speed requirement: Select the rated speed of the motor according to the speed required by the load. If the load requires variable speed, consider using a frequency converter to control the speed of the motor.

3. Voltage and frequency: The rated voltage and frequency of the motor should match the voltage and frequency of the power grid. If the voltage and frequency do not match, it may affect the performance and life of the motor.

4. Environmental conditions: Environmental conditions, such as temperature, humidity, and corrosiveness, must also be considered when selecting a motor. If the environmental conditions are harsh, it is necessary to select a motor with a suitable protection level.

5. Cost: Finally, the cost of the motor needs to be considered, including purchase cost and operating cost. Higher efficiency and longer life usually require higher cost inputs.

English

English Español

Español русский

русский عربى

عربى